Submitted by James Klim DDS, CADStar host on 12/01/2025 - 11:23am

Submitted by James Klim DDS, CADStar host on 01/21/2024 - 10:41am

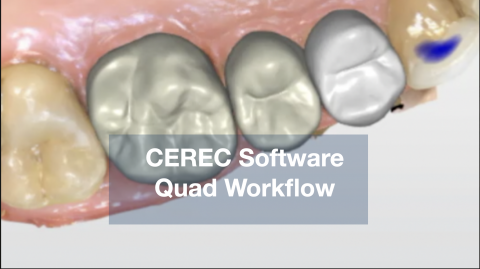

Quadrant chairside applications in the current CEREC software are predictable and efficient. This video will show the essential design steps and workflow so the quadrant restoration drops in.

Submitted by James Klim DDS, CADStar host on 06/23/2023 - 5:57pm

The workflow present in the video is the strategy I use to complete a veneer case in the same appointment. Several pointers will help the process. One, go in with a mock-up and complete the projects in sections, so the milling starts early in the appointment. Two, have a predictable design and milling strategy, have the glaze coloring system down, and gain outstanding results.

Submitted by James Klim DDS, CADStar host on 06/12/2022 - 8:00pm

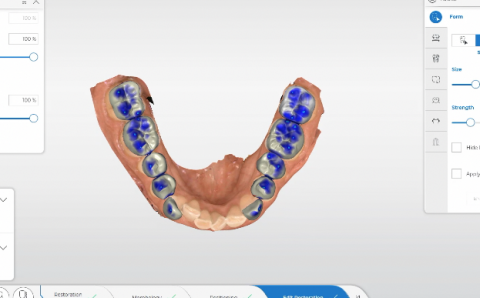

This video is the software workflow for a lower arch to open the bite with prepless onlays and veneers on the canine. The current software is working well! The transitional bite will be milled in composite material and bonded. This transitional occlusion will provide neural, muscle memory, and biomechanical adaptation before placing the final restorative restorations.

Submitted by James Klim DDS, CADStar host on 01/06/2022 - 5:57pm

Submitted by James Klim DDS, CADStar host on 06/17/2021 - 8:55am

When do we choose between an onlay vs. a crown? This video will review my take on the topic. I have been placing various forms of ceramic onlays for over 30 years and been able to track their endurance. And this treatment application has achieved excellent results, even before e.max. I will break down the five condition factors to consider when choosing an onlay vs. a crown and then provide a case review and onlay software workflow.

Submitted by James Klim DDS, CADStar host on 06/03/2021 - 6:46pm

Submitted by James Klim DDS, CADStar host on 03/19/2021 - 6:37pm

With the plethora of aesthetic zirconia materials, we are now capable of moving zirconia to the smile zone when it needs function and esthetics. This video tutorial is a case review about material choice and CEREC software workflow for an anterior bridge. In addition to designing each individual tooth within the bridge, the software presents a pontic baseline tool and connector design metrics to optimize the aesthetic and engineering design needs.

Submitted by James Klim DDS, CADStar host on 02/21/2021 - 1:14pm

Occlusal Offset will impact material thickness milled and occlusal calibration. This video will discuss how to arrive at an Occlusal Offset that is properly calibrated for your CEREC system and assure proper occlusal material thickness and occlusal contact firmness. Though this video is illustrated in CEREC Software version 4.65, the principles are the same for the current 5... version software.

Submitted by James Klim DDS, CADStar host on 02/14/2021 - 5:23pm